产品详情

Hastelloy B- 3

Common Trade Names: Hastelloy B3; Alloy B3;

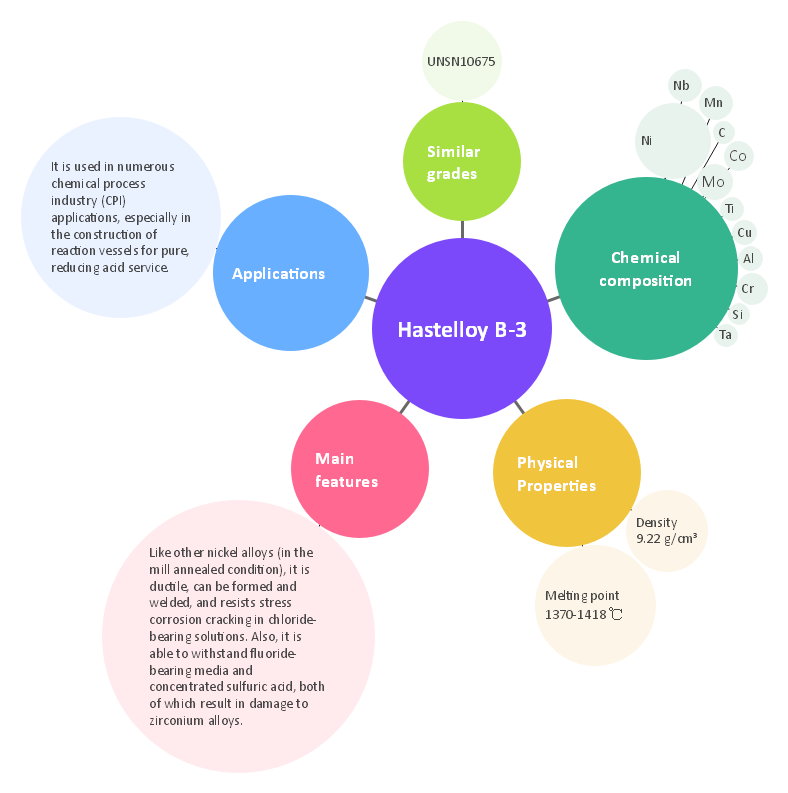

HASTELLOY B- 3 alloy (UNS N10675) is an excellent resistance alloy to hydrochloric acid at all concentrations and temperatures. It also withstands sulfuric, acetic, formic and phosphoric acids, and other nonoxidizing media. B- 3 alloy has a special chemistry designed to achieve a level of thermal stability greatly superior to that of its predecessors, HASTELLOY B- 2 alloy. B- 3 alloy has excellent resistance to pitting corrosion, to stress-corrosion cracking and to knife-line and heat-affected zone attack.

Available Product Forms:

Pipe, tube, sheet, strip, plate, round bar, flat bar, forging stock, hexagon, wire and extruded section.

|

Forms |

Classification |

Specification |

|

Forgings |

Round |

Φ30~Φ350 |

|

Rectangle |

30x 30~350x350 |

|

|

Hot rolled |

Disc, Sleeve, Flange, Ring |

As request |

|

Round |

Φ8.5~Φ80 |

|

|

Flat |

4x 60~50x300 |

|

|

Cold drawn (polished) |

Bar |

Φ2~Φ60 |

|

Wire |

Round |

Φ0.1~Φ8 |

|

Shaped wire |

As request |

|

|

Tubing |

Shell |

Φ76~Φ200 |

|

Cold drawn cold rolled pipe |

Φ6.0 x 0.6mm ~Φ200 x 20mm |

|

|

Cold rolled strip |

0.1 x 3.5 x L ~ 20 x 200 x L |

|

|

Sheet, Plate |

0.7≤T≤25,W≤1200,L≤3000 |

Similar Grades:

|

UNS |

|

N10675 |

HB-3Chemical Composition:

|

Grade |

% |

Ni |

Cr |

Mo |

Nb |

C |

Mn |

Si |

Co |

Cu |

Al |

Ti |

Ta |

|

HB-3 |

Min |

65 |

1.0 |

27.0 |

|||||||||

|

Max |

3.0 |

32.0 |

0.2 |

0.01 |

3.0 |

0.31 |

3.0 |

0.20 |

0.50 |

0.20 |

0.20 |

HB-3Physical Properties:

|

Density |

9.22g/cm3 |

|

Melting Point |

1370-1418℃ |

HB-3The minimum value of the mechanical properties of an alloy at room temperature:

|

Status |

Tensile strength Rm N/mm² |

Yield strength Rp 0.2 N/mm² |

Elongation A5 % |

|

Solid solution treatment |

860 |

420 |

50 |

Hb-3 Application:

It is used in numerous chemical process industry (CPI) applications, especially in the construction of reaction vessels for pure, reducing acid service.

Recommended Products

-

IncoloyA-286

United States designation UNS: S66286

German brand W. NR.: 1.4980

Executive standard AMS: 5525, 5732, 5737, 5804

GE: B50T1181, B50T12, B50T812022-12-20 -

Inconel 718

2022-12-20 -

Inconel X750

Common Trade Names: Inconel X750, Haynes X750, Alloy X750, Nickel X750, Pyromet X750, NickelvacX750, Nicorros®70162022-12-20 -

Hastelloy B- 3

2022-12-20 -

Hastelloy B

Alloy Hastelloy B is widely used in chemical, petrochemical, energy manufacturing and pollution control fields, especially in sulfuric acid, hydrochloric acid, phosphoric acid, acetic acid and other industries.2022-12-20 -

Nimonic80A

Nimonic80A is a nickel-based superalloy consisting of nickel-chromium. Nickel-based superalloys with excellent high-temperature mechanical properties, high creep strength, high corrosion resistance and oxidation resistance under high temperature and high pressure, these advantages make Nimonic80A widely used in aviation, aerospace, power stations, transportation and other high-temperature hot forgings. The addition of aluminum and titanium to form a gamma phase dispersion strengthened high tempe2022-12-21